In the field of modern industrial automation, flexible force control system has become one of the important technologies to improve production accuracy and efficiency. It is mainly used in the fields of robots, intelligent assembly, precision manufacturing, etc., and can achieve precise control of external contact force, so that the equipment can maintain stability and flexibility in complex operations. Choosing a suitable flexible force control system can not only improve production efficiency, but also effectively reduce damage and improve product quality. So, how to choose the most suitable flexible force control system for your needs?

1. Understand the working principle of the flexible force control system

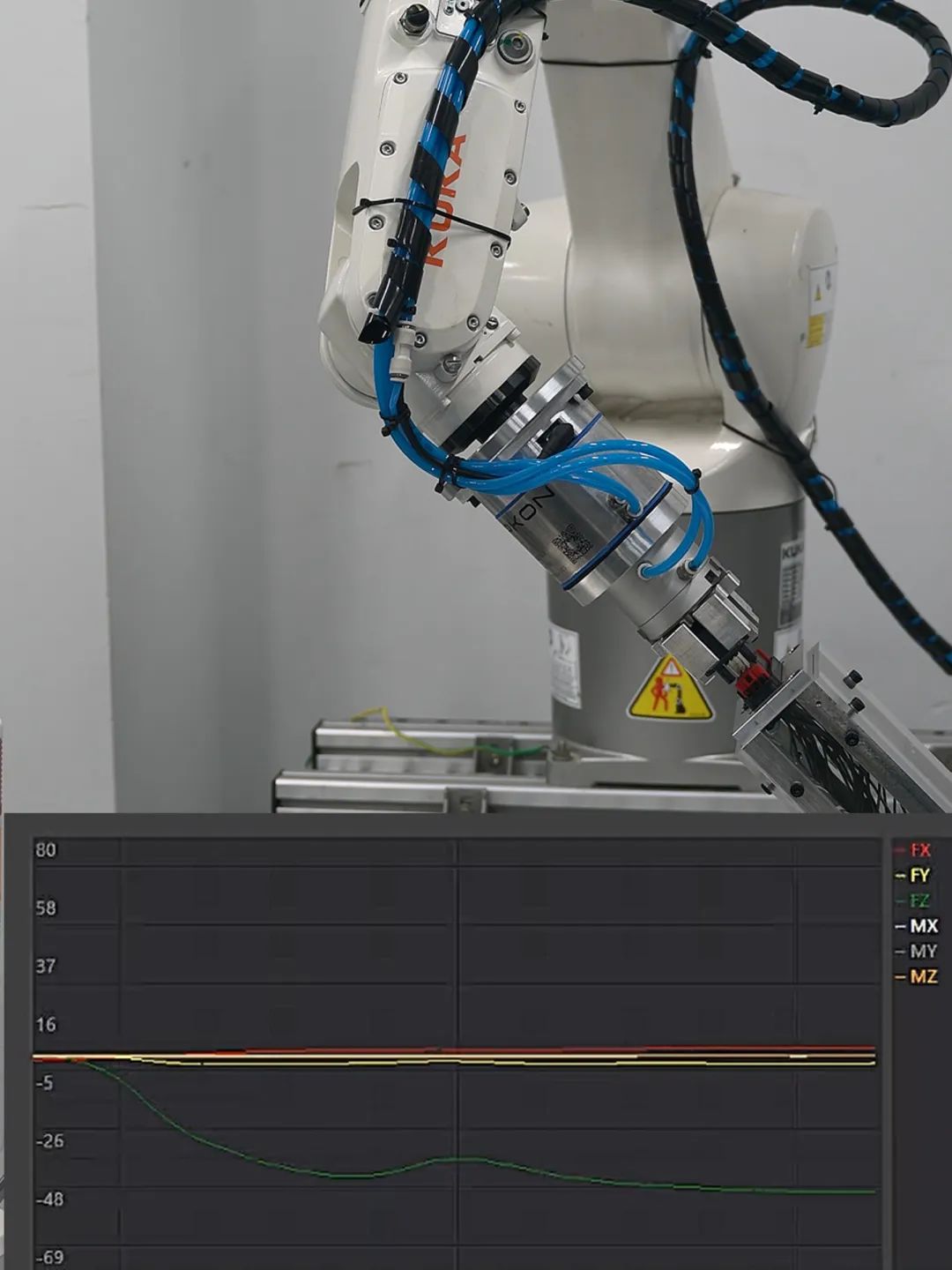

Before purchasing flexible force control systems, you first need to understand their basic working principle. The flexible force control system is a comprehensive system based on force/torque sensors, closed-loop control algorithms and motion control technology. It can sense the force of the external environment and adjust the movement of the robot or actuator in real time according to the set control strategy to make it flexible and adaptable. For example, in the process of precision assembly, the flexible force control system can be fine-tuned according to the contact force of the parts to avoid damage to the components and improve assembly accuracy.

2. Core factors for selecting flexible force control systems

2.1 Determine the application scenario and needs

Different application scenarios have different requirements for flexible force control systems, and the selection of the system needs to be combined with actual needs. For example:

Precision assembly: requires a high-sensitivity, high-precision force control system to ensure that the force changes during the assembly process are controlled to avoid damage to parts;

Polishing and grinding: The system needs to have dynamic adjustment capabilities so that the robot can adapt to the contact force changes of complex surfaces;

Medical surgical robots: require extremely high safety and stability to ensure operational accuracy;

3C electronic manufacturing: For the processing of small parts, high response speed and ultra-fine force control capabilities are required.

2.2 Force control accuracy of the system

The core capability of the flexible force control system lies in the perception and control of force, and its accuracy determines the reliability of the system. Usually, we need to pay attention to the following key parameters:

Force control sensor accuracy: whether it can detect tiny force changes.

Force control response speed: the feedback speed of the system to external force changes.

Force control stability: whether it can maintain consistent force feedback during long-term operation.

High-precision force control systems can provide more accurate feedback, thereby improving process quality and reducing product defective rates.

2.3 Compatibility and integration capabilities

Flexible force control systems often need to be integrated with existing equipment and software, so compatibility is a factor that must be considered when selecting. Mainly include:

Whether it supports mainstream industrial robot brands, such as ABB, FANUC, KUKA, YASKAWA, etc.

Whether it is compatible with common industrial bus protocols, such as EtherCAT, Modbus, CANopen, etc.

Whether it can be connected with PLC, SCADA, MES, and other systems to achieve complete automation control.

A system with strong compatibility can reduce the difficulty of implementation, improve work efficiency, and reduce the cost of subsequent upgrades.

2.4 The rigid-flexible switching capability of the system

The core advantage of the flexible force control system lies in its rigid-flexible switching capability, that is, it can flexibly adjust the force control mode under different working conditions. For example, a flexible mode is required for fine assembly, while a rigid mode may be required for fixed clamping. Therefore, an excellent force control system should have the ability to switch quickly to adapt to different process requirements.

2.5 Convenience of operation and programming

Modern flexible force control systems usually use intelligent programming methods to make them easy to set up and adjust. When choosing a system, you need to consider:

Whether it supports graphical programming or drag-and-drop programming to reduce the operating threshold.

Whether it has an automatic force control adjustment function to reduce manual debugging costs.

Whether it supports remote monitoring and maintenance to improve production management efficiency.

An easy-to-operate system can not only shorten the deployment cycle, but also reduce dependence on professional technicians and improve the overall production efficiency of the enterprise.

2.6 Safety and reliability

In industrial production, safety is a factor that must be considered when selecting any equipment. In actual applications, the flexible force control system may involve human-machine collaboration scenarios, so safety design is crucial. When selecting a system, you need to focus on:

Whether it has an overload protection function to avoid damage caused by excessive external force.

Whether it supports collision detection function to ensure the safety of human-machine interaction.

Whether it has stable working performance and can operate for a long time in a complex environment.

A system with strong reliability can effectively reduce the failure rate, reduce maintenance costs, and improve production continuity.

2.7 Cost-effectiveness

The price of the flexible force control system varies depending on factors such as brand, performance, and function. When choosing, you need to comprehensively evaluate the cost and benefits. Generally, it is recommended to choose products that can operate stably for a long time, have perfect technical support, and are cost-effective, rather than just pursuing low prices.

3. Steps to choose a flexible force control system

In order to choose a suitable flexible force control system more efficiently, you can follow the following steps:

Clear requirements: determine the application scenario, and clarify the requirements for accuracy, force feedback, and compatibility.

Compare brands: Combine market research to select brands and models that meet the requirements.

Testing and verification: Before formal purchase, conduct prototype testing to verify the stability and compatibility of the system.

Cost evaluation: Comprehensively consider the purchase cost, maintenance cost, and upgrade cost to ensure the maximum return on investment.

After-sales service: Give priority to brands that provide perfect technical support and after-sales service for subsequent maintenance.

As an important part of intelligent manufacturing, flexible force control systems are being used by more and more industries. To choose a suitable system, it is necessary to comprehensively consider multiple angles such as application requirements, accuracy, compatibility, and safety, and combine brand comparison and actual testing to ensure that the system can meet production requirements. Only by choosing flexible force control systems that suit business needs can we truly improve the level of automation and achieve more efficient production and management. I hope the content of this article can help you.

Shanghai Dapkon Technology Co., Ltd

dapkon